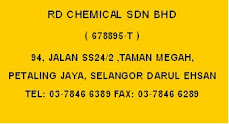

RD CHEMICAL SDN BHD

Address: 94, Jalan SS24/2, Taman Megah, 47301 Petaling Jaya, Selangor. Tel : 603-784 66389 Fax : 603-784 66289

1) BOIL-TREAT BOILER WATER TREATMENT CHEMICALS

BOILER WATER TREATMENT PROGRAM

Steam generating boilers of all designs require Boiler Chemical Treatment and are subject to the same problems namely boiler scale, boiler corrosion, steam/ condensate system corrosion and producing steam of adequate quality.

Since even minute amounts of dissolved and suspended water impurities can cause problems a follow-up treatment is needed regardless of how the water is prepared. A complete boiler water treatment program includes: -

Oxygen Scavenger - Designed for fast removal of oxygen and corrosion to protect interior of stream boiler.

Scale and Deposit Control - Designed to protect interior of steam boiler from scaling, sludge and overheated.

Alkalinity Booster – Consists of strong alkali and organic dispersant for pH adjustment. To protect steam boiler from pitting.

Sludge Dispersant and Online Cleaning – Designed for removing sludge especially at the base of boiler during blow down to control deposition of mineral on the interior surface of steam boiler and also to prevent from overheating.

Our program recommendation ensures longer life span of steam boiler.

2) COOL-TREAT COOLING TOWER TREATMENT CHEMICALS

COOLING TOWER TREATMENT PROGRAM

2(i) BACTERIA IN COOLING TOWER

A problem that develops in all exposed evaporative systems is the evolution of aquatic growth. Many forms of algae, bacteria, molds and fungi thrive in this environment. This condition is exacerbated by the action of the cooling tower where the system functions as a giant scrubber removing particulates from the air. These particulates in themselves cause problems by contributing directly to deposit formation. In many cases they can also become a food source for bacteria. Heavy infestations of bacteria will result in slime and biofilm development. Biofilms as with other forms of deposition will result in reduced operating efficiency and corrosion.The presence of many bacterial strains such as Legionella Pneumophila represents serious hazards to human health. (i.e Legionaires Disease) This type of bacteria is normally carried in airborne water droplets. The water droplets can be passed into the heating and cooling ducts and end up where people live and work.

It is extremely important for many reasons that Cooling systems are maintained as clean and corrosion free as possible. Bacteria and other forms of aquatic growth must also be controlled within acceptable limits.

Our

Our preventive treatment program are :

Algae and Fungi Inhibitor - To help remove algaecide around the cooling tower, there by increasing the efficiency of the cooling effect and save on electrical consumption through constant usage of the chemical.

Corrosion and Scale Inhibitor - Designed for scale, corrosion and sludge control in cooling tower.

Micro-Biocides Agent – Highly effective to bacterial and fungal slime from growing in cooling tower.

3) WASTE WATER TREATMENT PROGRAM

Waste water is any water that has been adversely affected in quality by anthropogenic* influence. It comprises liquid waste discharged by domestic residences, commercial properties, industry, and/or agriculture and can encompass a wide range of potential contaminants and concentrations. In the most common usage, it refers to the municipal wastewater that contains a broad spectrum of contaminants resulting from the mixing of wastewaters from different sources.

3i) Industrial Waste Water Treatment

Industrial wastewater treatment covers the mechanisms and processes used to treat waters that have been contaminated in some way by man's industrial or commercial activities prior to its release into the environment or its re-use.

3ii) Sources of Industrial Wastewater

· Agricultural waste

· Iron and steel industry

· Mines and quarries

· Food industry

· Complex organic chemicals

· industry

· Water treatment

3iii) Treatment of Industrial Waste water

· Solids removal

· Oils and greases

· Soft organics

· Hard organics

· Acids and alkalis

· Toxic materials